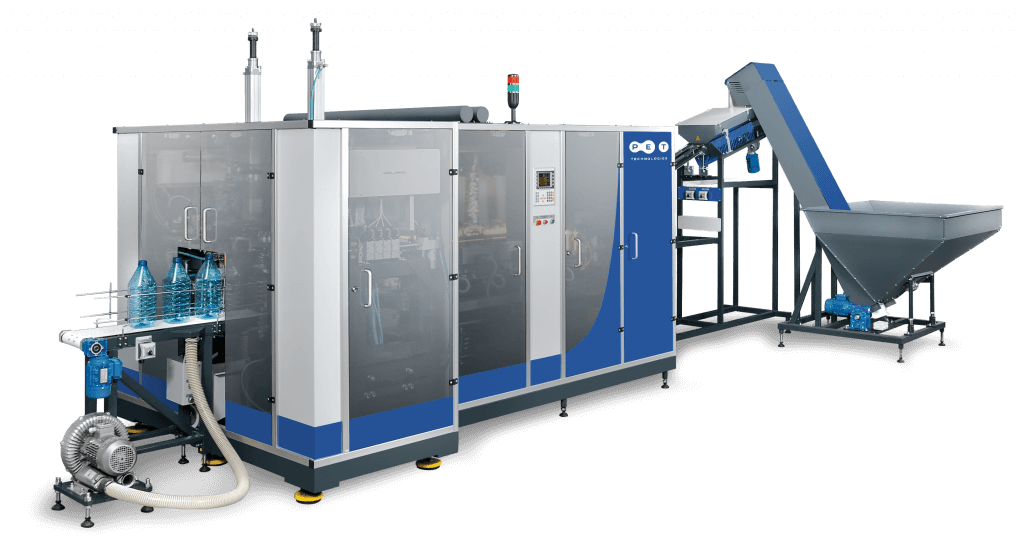

Stretch Blow Molding Machine APF-5

- Type: Automatic

- Production Volume: 3 - 10 L

- Output: up to 1600 bph

Automatic blow molding machine for bottles with volume 3.0-10.0l and output 1 600 bph. Two independent blowing units to produce 2 bottle formats by turns.

Features

2 independent blowing units to produce 2 bottle formats/volumes by turns

8-zone quick and intensive preform heating system

Air recovery system – reuse of compressed air to cover 100% of low pressure line demand

Bottle oriented outfeed system to connect with filling line

CE certificate and conformity with HACCP

Full automation via B&R company PLC system

Mold closing system similar to rotary machines

Reliable and steady mold closing system

Separate block of valves for each mold cavity

Servodrive for heated preform transfer to the blow mold

Stretching rods designed 5 – 10 L bottles thick-walled preform

Application

- Water and CSD

- Oil and vinegar

- Output: 1 600 bph with volume of 3-8 l OR up to 1 200 bph with volume of 10 l

- Bottle volume: 3 – 10 L

- Blowing pressure: 8-10 bar

- Low pressure: up to 30 bar

- Low and high pressure air demand: 5 m³/min

- Cooling liquid temperature: 7-9 °С

- Voltage supply: 400 V / 50 Hz

- Installed power: 46 kW

- Overall dimensions: 7400 х 3200 х 2720 mm

- Weight: ~ 4 600 kg

Need more information?