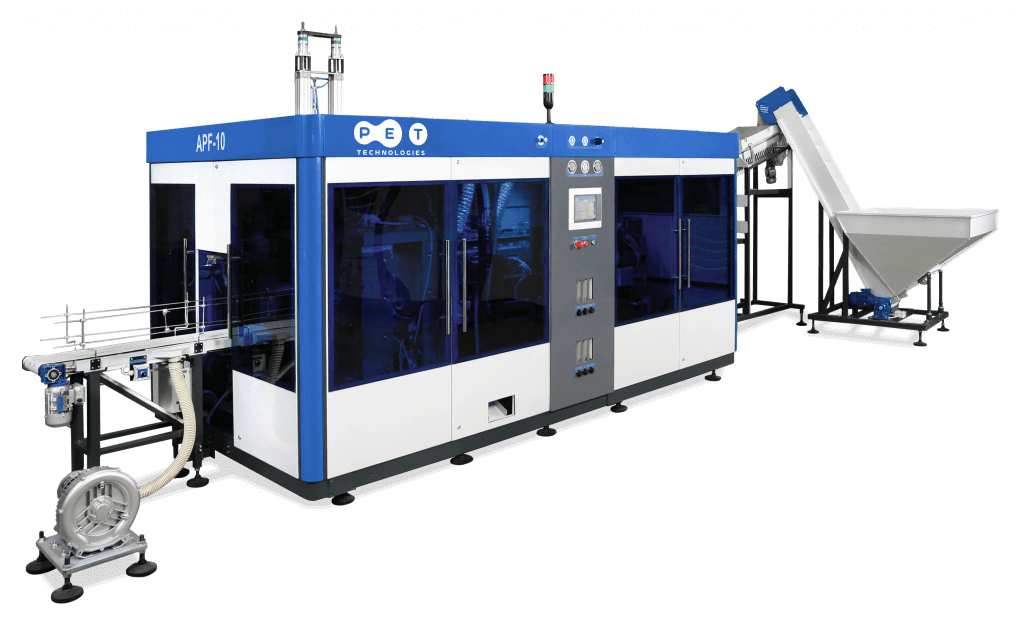

Stretch Blow Molding Machine APF-10

- Type: Automatic

- Production Volume: 3 - 10 L

- Output: up to 2500 bph

Features & Application

Specification

Video

Features & Application

Automatic blow molding machine for bottles with volume 3.0-10.0l and output 2 500 bph. Separate block of valves for each mold cavity designed by PET Technologies R&D.

Features

- 8-zone quick and intensive preform heating system

- Air cooling system for uniform preform heating

- Air recovery system – reuse of compressed air to cover 100% of low pressure line demand

- Bottle oriented outfeed system

- CE certificate and conformity with HACCP

- Full automation via B&R company PLC system

- Reliable and steady mold closing system

- Separate block of valves for each mold cavity

- Servodrive for heated preform transfer to the blow mold

- Stretching rods designed 5 – 10 L bottles thick-walled preform

Application

- Water and CSD

- Oil and vinegar

Specification

- Output: 2 500 bph with volume of 3-8 l OR up to 1 800 bph with volume of 10 l

- Bottle volume: 3 – 10 L

- Blowing pressure: 8-10 bar

- Low pressure: up to 30 bar

- Low and high pressure air demand: 10 m³/min

- Cooling liquid temperature: 7-9 °С

- Voltage supply: 400 V / 50 Hz

- Installed power: 68 kW

- Overall dimensions: 8200 х 3400 х 2600 mm

- Weight: ~ 6 800 kg

Video

Need more information?